We can deliver a range of digitalization & automation services. Our experience supporting clients who include EPC contractors means we are well-positioned to help improve your plant’s reliability, efficiency, and operations. And in the process, strengthen your bottom line.

At BWSC, we can offer the following Automation services:

- Complete Industrial Automation and Control Systems (IACS) services for new power plants – design, engineering, and installation

- IACS upgrade and maintenance activities

- Secure network infrastructure architecture design for the entire Information Technology (IT) and Operation Technology (OT) plant environment.

We also offer the following Digitalization services:

- Cyber Security Management Services (IEC 62443)

- Digitalization includes secure data transformation (Industry 4.0/5.0)

- Service agreements which include online Control System service support, remote monitoring & troubleshooting, security patch management, security network monitoring and health check monitoring.

In particular, we look to support our client’s Control & Safety Systems (SCADA & DCS) Upgrade.

As the Control System of your plant ages, it poses a significant risk to the power production process through unplanned downtime and higher maintenance costs.

At BWSC, we support your business transformation through a state-of-the-art, tailor-made Control Systems and for high availability solutions, we recommend Distributed Control System (DCS). In addition, we possess a wealth of knowledge developed through engagement and support of a variety of client-specified architecture requirements.

BWSC is an agnostic integrator that primarily are working with Control & Safety solutions from well-known suppliers as ABB (800xA, Compact HMI), Siemens (SIMATIC PCS7 & WinCC) and Rockwell Automation (ControlLogix). We have a vast experience integration a variety of DCS & SCADA Control Systems from many different vendors.

Our approach

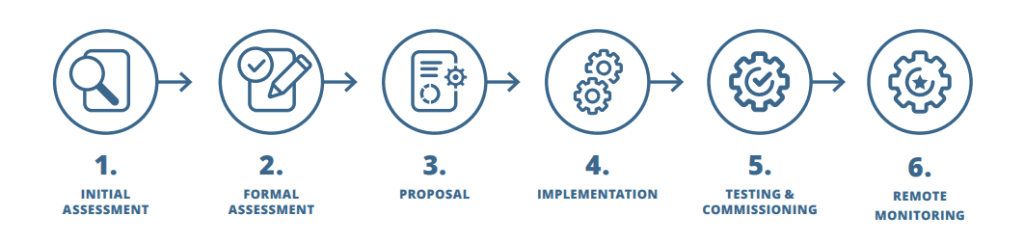

To ensure a smooth and successful outcome to the implementation of a Control System upgrade, we follow a 6-step approach to satisfy your requirements:

A Control System upgrade with BWSC involves the following activities:

- Replacement of IT, network equipment and control system hardware

- Upgrading control network, server, and workstations

- Improving the ability to monitor alarms, events, and other plant data, adding redundancy

- Integration of different control technologies into a single system

Furthermore, BWSC offers Service Agreements tailored to the client’s needs to support plant uptime and ensure the highest power plant availability.

In addition, the Service Agreement seeks to protect your plant and business from unexpected breakdowns or failures of the Control System that may cause financial losses.

Clients can choose from a range of support services, including:

- On-site and on-call support, including remote health checks.

- Maintenance site visits, including Software & Hardware health check, capacity checks, battery replacement, security patching and backup/restore testing etc.

- Remote monitoring of the systems including cyber security events like Endpoint Protection, backups to full 24/7 Network Operation Center (NOC) and 24/7 Security Operation Center (SOC)

- Instrumentation and Control engineering specialist support both remote and onsite